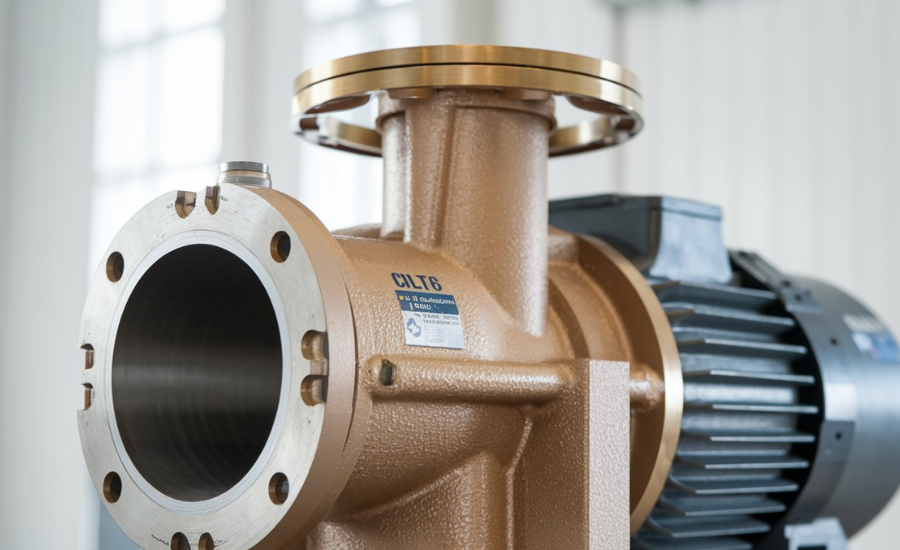

The Allweiler clt6 Pump No Wear Ring no wear ring is celebrated for its advanced fluid handling capabilities, characterized by its distinctive design—most notably, the omission of a wear ring. This innovative feature significantly boosts the pump’s operational efficiency and minimizes maintenance requirements, making it an optimal choice for industries that depend on dependable pumping solutions. By forgoing the wear ring, the CLT6 pump effectively reduces friction and potential wear on components, which contributes to its durability and consistent performance over time. This pump is particularly suited for applications that prioritize long-lasting operation and low maintenance needs, demonstrating Allweiler’s dedication to enhancing pump technology and catering to the varied demands of its customers.

Exploring The Allweiler clt6 Pump No Wear Ring Without A Wear Ring

The Allweiler clt6 Pump No Wear Ring no wear ring is unique due to its design that omits the wear ring, a component commonly found in many traditional pumps. This innovative feature sets the CLT6 apart, reducing the number of parts susceptible to damage and enhancing overall reliability. As a result, this pump operates longer without the need for repairs, making it an excellent choice for industries requiring dependable fluid handling solutions.

By eliminating the wear ring, the CLT6 pump minimizes internal friction—the resistance that occurs when components interact. Lower friction means smoother operation, contributing to its suitability for industries that prioritize reliability and efficiency.

Additionally, the CLT6 pump simplifies maintenance processes. With fewer components to monitor or replace, businesses can allocate their time and resources more effectively, focusing on productivity rather than upkeep. This convenience is why many companies are increasingly opting for the Allweiler clt6 Pump No Wear Ring no wear ring in their fluid management systems.

Why The Allweiler clt6 Pump No Wear Ring Without a Wear Ring Is Revolutionary

The absence of a wear ring in the Allweiler clt6 Pump No Wear Ring no wear ring is a transformative aspect for several reasons. Firstly, this design leads to energy conservation. With reduced internal friction, the pump requires less energy to operate, resulting in lower operational costs—an appealing factor for businesses looking to enhance their bottom line. Over time, these energy savings can accumulate significantly.

Moreover, the durability of the CLT6 pump is noteworthy. Fewer parts mean reduced wear, contributing to a longer lifespan. In industries where equipment longevity is crucial, this durability provides a competitive edge, allowing companies to invest confidently in a pump that won’t need frequent replacements.

Key Benefits Of The Allweiler clt6 Pump No Wear Ring

- Energy Efficiency: Operates with reduced power consumption.

- Longevity: Designed to withstand the test of time with fewer repair needs.

- Low Maintenance: Streamlined design results in less upkeep.

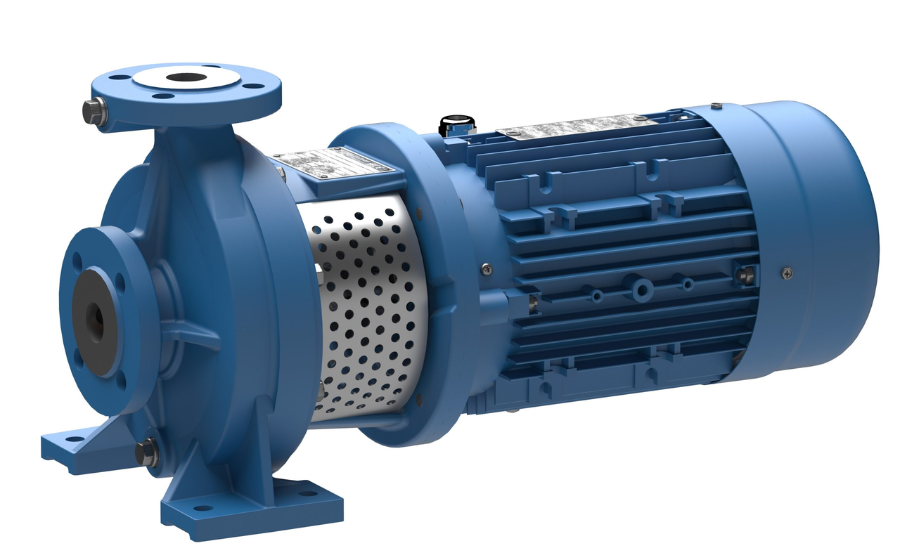

In addition to its robust features, the Allweiler clt6 Pump No Wear Ring no wear ring is versatile, suitable for various applications across sectors such as chemical processing, water treatment, and beyond. Its capacity to manage different types of fluids makes it a flexible solution, seamlessly integrating into diverse operational environments. This adaptability positions the CLT6 pump as a reliable option for businesses seeking efficient and dependable pumping systems.

Innovative Design Of The Allweiler clt6 Pump No Wear Ring

The Allweiler clt6 Pump No Wear Ring no wear ring represents a significant advancement in pump technology, celebrated for its unique design that does away with the conventional wear ring. This thoughtful omission simplifies the pump’s construction while enhancing its reliability, making it an exceptional option for fluid handling applications. By eliminating the wear ring, the CLT6 pump reduces the number of components prone to wear, contributing to its extended operational lifespan. This innovative strategy underscores Allweiler’s dedication to producing high-performance pumps tailored to meet the evolving demands of modern industries. It is a progressive solution that caters to the efficiency needs of today’s businesses.

Efficiency Redefined

The design of the Allweiler clt6 Pump No Wear Ring no wear ring without a wear ring greatly enhances operational efficiency, setting a new benchmark in the pump sector. The removal of the wear ring results in decreased internal friction, leading to smoother operation and lower energy requirements. These efficiency improvements are especially advantageous for large-scale industrial settings where energy expenses can significantly impact the bottom line. Furthermore, the streamlined architecture enables the pump to run continuously with minimal maintenance, maximizing uptime and productivity. This makes it an excellent choice for companies aiming to optimize their operations and lower operational costs.

How The Allweiler clt6 Pump No Wear Ring Without A Wear Ring Operates

The Allweiler clt6 Pump No Wear Ring no wear ring is ingeniously designed to function without a traditional wear ring, utilizing an innovative sealing system instead. This system effectively contains fluids while minimizing friction, resulting in a pump that operates smoothly and efficiently.

Additionally, the CLT6 is constructed with advanced materials that enhance its performance across a range of fluid types, whether they are viscous or thin. This versatility allows the pump to excel in various operational environments, catering to the diverse requirements of multiple industries.

Key Features:

- Sealing Mechanism: Effectively retains fluids without a wear ring.

- High-Performance Materials: Capable of handling different fluid types.

- Efficient Operation: Minimizes friction for superior performance.

In summary, the design of the Allweiler clt6 Pump No Wear Ring no wear ring enables it to achieve exceptional efficiency. Its innovative construction positions it well to tackle the challenges faced by modern industries. For companies in search of effective pumping solutions, this pump proves to be a trustworthy option.

Advantages Of The Allweiler clt6 Pump No Wear Ring =Without a Wear Ring

Opting for the Allweiler clt6 Pump No Wear Ring no wear ring offers numerous benefits. One significant advantage is cost savings. With reduced maintenance requirements and an extended lifespan, businesses can lower their expenses related to repairs and replacements, making it a wise investment.

Another advantage is enhanced efficiency. The CLT6 pump’s design enables it to transport fluids more quickly and effectively. Improved pump performance translates to greater productivity across operations, allowing businesses to achieve more with less effort.

Benefits of the Allweiler clt6 Pump No Wear Ring no wear ring:

- Cost Savings: Lowers repair and maintenance costs.

- Enhanced Efficiency: Facilitates rapid fluid movement.

- Increased Productivity: Enables businesses to maximize output.

Moreover, this pump is environmentally friendly. Its energy-efficient operation contributes to a reduced carbon footprint, aligning with the growing emphasis on sustainability in business practices. The Allweiler clt6 Pump No Wear Ring no wear ring supports companies in their efforts to adopt eco-conscious solutions, making it a responsible choice for today’s environmentally-aware industries.

Extended Durability

When selecting industrial equipment, durability is a crucial consideration, and the Allweiler clt6 Pump No Wear Ring no wear ring without a wear ring excels in this aspect. By eliminating the wear ring, the risk of component wear and tear is significantly reduced, allowing the pump to maintain peak performance for longer periods. This durability translates to a lower total cost of ownership, as the pump demands less frequent repairs and replacements. This engineering robustness underscores the reliability of the CLT6 pump, making it a prudent investment for industries where longevity and dependability are essential.

Versatile Applications

The Allweiler clt6 Pump No Wear Ring no wear ring without a wear ring is not only durable and efficient but also remarkably versatile, making it suitable for a variety of applications. Whether in chemical processing or water treatment, this pump adeptly addresses the diverse requirements of different sectors. Its capability to manage various fluids without the complications associated with a wear ring adds to its appeal for businesses seeking dependable fluid handling solutions. The innovative design of the pump ensures consistent performance across multiple environments, distinguishing it in a competitive marketplace.

Environmental Benefits

In an era increasingly focused on sustainability, the Allweiler clt6 Pump No Wear Ring no wear ring offers environmental benefits by minimizing the need for replacement parts, thereby reducing waste. With fewer components needing replacement, the pump plays a role in lowering industrial waste and aligns with eco-friendly practices. Additionally, its efficient operation contributes to reduced energy consumption, aiding businesses in lessening their carbon footprint. This environmentally conscious feature makes the CLT6 pump an excellent choice for companies dedicated to sustainable operations. Allweiler’s commitment to eco-friendly solutions reflects its corporate responsibility and innovative spirit.

Economic Advantages

From an economic standpoint, the Allweiler clt6 Pump No Wear Ring no wear ring without a wear ring offers a range of benefits, making it a financially sound choice for businesses. The combination of lower maintenance needs and extended durability results in substantial savings throughout the pump’s lifespan. This allows companies to allocate resources more effectively, focusing on growth rather than ongoing repairs or replacements. Furthermore, the pump’s energy efficiency leads to reduced utility costs, enhancing its economic attractiveness. By choosing the CLT6 pump, businesses can achieve operational excellence and financial efficiency, securing a competitive advantage within their industries.

Streamlined Maintenance with the Allweiler clt6 Pump No Wear Ring No Wear Ring

The Allweiler clt6 Pump No Wear Ring no wear ring designed without a wear ring simplifies maintenance significantly compared to conventional pumps. By eliminating the wear ring, which typically necessitates regular inspections and replacements, this pump reduces the number of components that require attention. As a result, operators can dedicate less time to maintenance activities.

For many companies, routine maintenance can be a burden, often leading to unplanned downtime that disrupts production and increases operational costs. The Allweiler clt6 Pump No Wear Ring no wear ring addresses these challenges by minimizing maintenance requirements, allowing businesses to maintain continuous operations without interruptions.

Maintenance Made Easy:

- Fewer Components: Less to inspect and replace means streamlined upkeep.

- Minimized Downtime: Ensures consistent production flow.

- Reduced Burden: Operators can concentrate on core tasks instead of routine checks.

In summary, the Allweiler clt6 Pump No Wear Ring no wear ring without a wear ring provides a more manageable maintenance experience. This enables companies to enhance their operational efficiency and effectiveness, allowing them to focus on achieving their objectives without the constant worry of pump upkeep.

FAQs About The Allweiler clt6 Pump No Wear Ring

1. What is the primary advantage of the Allweiler clt6 Pump No Wear Ring no wear ring having no wear ring?

The primary advantage is reduced maintenance requirements. The absence of a wear ring means fewer components to check and replace, leading to lower downtime and operational costs.

2. How does the design of the Allweiler clt6 Pump No Wear Ring no wear ring improve efficiency?

Without the wear ring, the pump experiences less internal friction, resulting in smoother operation and decreased energy consumption. This enhances overall efficiency, especially in large-scale industrial applications.

3. Is the Allweiler clt6 Pump No Wear Ring no wear ring suitable for various types of fluids?

Yes, the Allweiler clt6 Pump No Wear Ring no wear ring is designed to handle a wide range of fluids, including both thick and thin substances. Its innovative design allows it to perform effectively across diverse industrial environments.

4. What maintenance is required for the Allweiler clt6 Pump No Wear Ring no wear ring?

Maintenance is minimal compared to traditional pumps. Regular inspections are still recommended, but the lack of a wear ring means fewer parts need attention, making it easier for operators to manage.

5. How does the Allweiler clt6 Pump No Wear Ring no wear ring contribute to sustainability?

The pump reduces industrial waste by minimizing the need for replacement parts and lowers energy consumption, helping companies decrease their carbon footprint and align with eco-friendly practices.

Conclusion

The Allweiler clt6 Pump No Wear Ring no wear ring, designed without a wear ring, stands as a groundbreaking solution for industries seeking efficient, durable, and low-maintenance pumping systems. Its innovative design minimizes friction, enhances operational efficiency, and reduces the frequency of repairs, making it a cost-effective choice for businesses. With the added benefit of versatility across different applications and a commitment to sustainability, the CLT6 pump aligns perfectly with modern industrial demands. By investing in the Allweiler clt6 Pump No Wear Ring no wear ring, companies can optimize their operations, reduce costs, and contribute to a more sustainable future.

Stay informed with the latest news and updates on Englandinsider